Discovering all the different things that you can create is one of the great joys of owning a vinyl cutting machine. But we’re sure we’re not the only ones that have been stumped about how to cut heat transfer vinyl.

What’s it for? How can I cut it? Where does the heat come from?!

All valid questions.

But never fear — after a brief ‘back to school’ learning curve, we’re here to hand down the tips and tricks you need to make vinyl heat transfer paper (also known as heat press vinyl) work for you.

Post Contents

What is Heat Transfer Vinyl Used for?

First things first, you’re probably wondering what exactly heat transfer vinyl is used for anyway.

Basically, it’s a type of vinyl material that needs to be ironed on to certain fabrics. Whereas most ‘normal’ vinyl will simply stick straight on to most hard surfaces, heat transfer vinyl must be heat pressed in order to adhere to softer fabrics.

The most common use of heat press vinyl is for T-shirt designs.

Crafters also use it for pillows, bags, other clothes and basically any other fabric you can think of. If you need an iron to stick the design on, then you need to use heat transfer vinyl.

How to Cut Heat Transfer Vinyl

Although working out how to cut heat transfer vinyl may seem a little overwhelming at first, it’s actually really simple once you get your head around it.

We would recommend starting small with a simple design on a cheap, $1 T-shirt. Once you’ve found your groove with heat transfer, you’ll be confident enough to progress on to the next level.

We’ve summarized below the process for Silhouette heat transfer vinyl and for Cameo heat transfer, as they’re the most popular machines in use right now.

Thankfully, the process doesn’t vary too much between vinyl cutting machines, so you’ll be able to follow these instructions and simply adapt them to your specific craft cutter.

How to Cut Heat Transfer Vinyl for Silhouette Cameo

Using heat transfer vinyl for Silhouette Cameo is simple and straightforward.

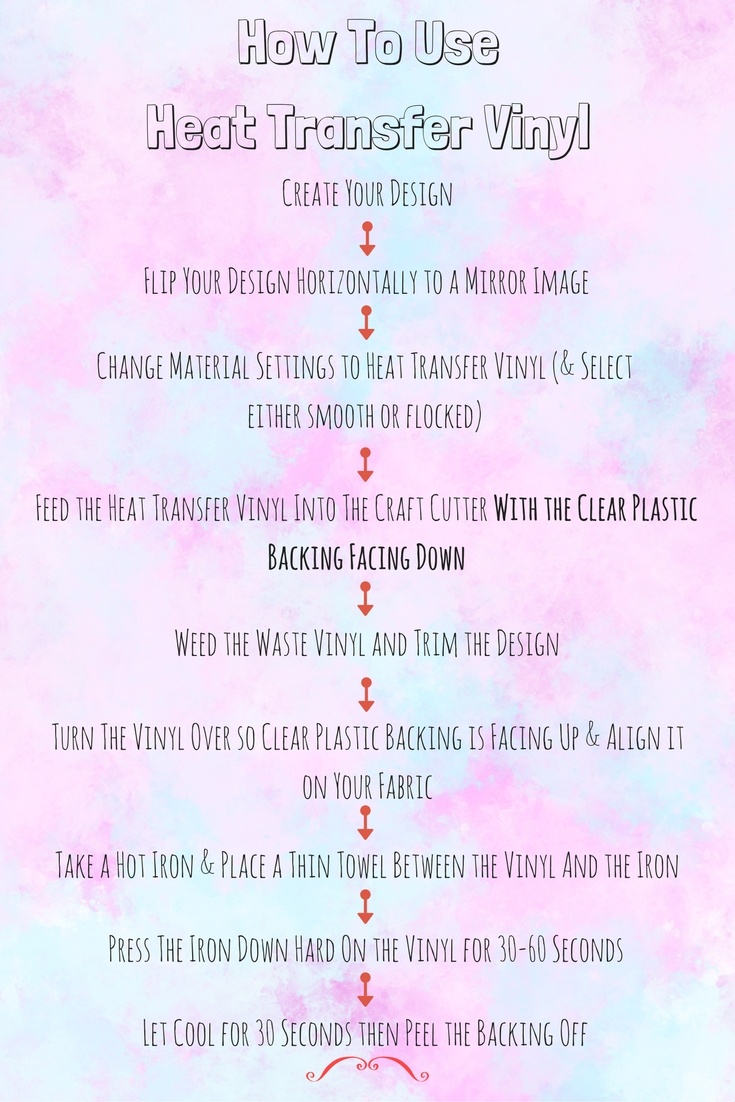

Here’s a step-by-step:

- Create your design within Silhouette Studio

- Flip your design horizontally so it’s a mirror image of the original (this is so the design is facing the right way when you iron it on). You can do this by selecting ‘Mirror’ from the drop-down ‘Object’ tab along the top, and then clicking ‘flip horizontally’

- Move the mirror image into the cutting area so it fits within the material

- Change the material settings to Heat Transfer Vinyl and select either ‘smooth’ or ‘flocked’ (a fluffier texture)

- Feed the heat transfer vinyl into the Cameo with the clear plastic backing facing down

- Click ‘Send to Silhouette’ to begin the cut job

Easy peasy!

Here’s a quick video tutorial for inspiration:

How to Cut Heat Transfer Vinyl for Cricut

It’s just as easy to use heat transfer vinyl for Cricut as it is for Silhouette.

Here’s a step-by-step guide:

- Create your design within Cricut Design Space

- Click the ‘Mirror image’ checkbox at the bottom of the Mat Preview window

- Place the heat transfer vinyl with clear plastic backing facing down on your cutting mat

- Select ‘Iron-On’ on the Smart Set Dial (in the Cricut Explore series) for matte and glossy materials, and the next setting clockwise (before ‘Light Cardstock’) if you’re using glitter heat transfer

- Then follow the instructions onscreen to load, set and cut

Here’s an easy video tutorial for how to use Cricut iron-on vinyl:

After the Cutting…

Once your machine has cut your design, remove it from the cutting mat and weed it as you would a normal vinyl cut.

Weeding is the act of removing all the waste vinyl from the design. Check out our guide to weeding and transferring if you’re a beginner.

Some people just use a safety pin or a bubble popper for weeding, but our pick for accuracy and speed is always the X-Acto Knife Set.

It’s also a good idea now to trim the material closely around your design so you’re only navigating around the heat press vinyl that you need.

Turn the vinyl over so the clear plastic backing is now facing up (and you’re looking at the original, not a mirror image) and place it on your fabric so you can correctly align it.

Once you’re satisfied, heat up your iron and take a thin towel, sheet of parchment paper or Teflon sheet and place it between the iron and the vinyl. Then, press the iron down, hard, on to the heat transfer vinyl for around 30 to 60 seconds. The vinyl you buy will specify the exact heat and pressing time you need, so check carefully before you dive in.

Remove the hot iron and allow the design to cool momentarily for around half a minute. After that time, start to peel the clear plastic backing off the design. If part of the vinyl design start coming off too, then you need to spend longer on the heat press. Only peel once the vinyl is thoroughly affixed to the fabric.

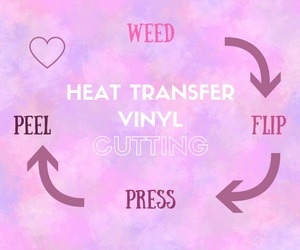

We call this process after the cut: WEED, FLIP, PRESS, PEEL.

Different Types of Heat Transfer Vinyl

There are lots of types of heat transfer vinyl to choose from before you get started.

First of all, you’ll need to choose between smooth and flocked material.

And from there, the world’s your oyster: glitter, matte, glossy, neon, foil or printable. The latter is great for more intricate, multicolored designs, which you can print on to the material before you cut it.

Let’s take a look at some of the heat transfer vinyl materials on offer from our favorite brands…

Cricut Iron On Vinyl

Here are a few of our favorites from their collection:

- Cricut Iron On Lite, White

- Cricut Iron On Lite, Black

- Cricut Iron On Glitter, Red

- Cricut Iron On Lite, Pumpkin

- Cricut Iron On Glitter, Fluorescent Pink

- Cricut Printable Iron-On for Scrapbooking

- Cricut Iron On Lite, Metallic Cyan

- Cricut Iron On Glitter, Lipstick

- Cricut Iron On Lite, Blush

Silhouette Heat Transfer Vinyl

And here’s a few of the most popular materials from Silhouette:

- Silhouette Smooth Heat Transfer 9″ x 36″ — Black

- Silhouette Glitter Heat Transfer 12″ x 36″ — Gold

- Silhouettte Printable Heat Transfer Material for Light Fabrics

- Silhouette Flocked Heat Transfer 12″ x 36″ — White

Heat Press Vinyl by Other Brands

If you haven’t got a Silhouette or Cameo machine, or if you simply want to try different brands, then check out the slew of other heat press vinyl materials on offer.

The only thing to remember is that you need to buy the correct size for your machine (or be prepared to trim it down accordingly!).

Here are the most popular heat transfer vinyl alternatives:

- Siser EasyWeed Heat Transfer Vinyl, 12″ x 15″, Color Starter Bundle

- Firefly Craft Heat Transfer Vinyl for Silhouette and Cricut, 12″ x 20″

- Rozzy Crafts 12 Color Heat Transfer Vinyl Starter Pack, 12″ x 10″

- Siser Glitter Heat Transfer Vinyl, 10″ x 12″, 12 Color Starter Bundle

- Outus Glitter Heat Transfer Vinyl, 6 Sheets in Assorted Colors

What You Need to Get Started

If you’ve got this far, you’re probably raring to get going with heat transfer vinyl cutting.

Here’s a quick checklist of everything you need before you start.

- A vinyl cutting machine (duh! Check out the best ones here)

- Heat transfer vinyl (see above for options)

- T-shirt, or whichever fabric you’re using

- Iron or a specialist heat press

- Towel, parchment paper or Teflon sheet

- X-Acto Knife Set for weeding

And, of course, your imagination…

Quick Tips

Working out how to use heat transfer vinyl can be a little overwhelming, so we would suggest starting small until you’re more confident with the process.

The Pinning Mama mentions that using flocked vinyl is more forgiving than smooth, and we agree. Any small errors in the weeding or peeling process are generally lost in the texture of the flocked material, whereas they stand out clearly on the smooth vinyl.

Glitter heat transfer vinyl can be tricky to weed so we’d only recommend using it once you’ve gotten used to it with normal vinyl cutting.

Start with a simple, one color design for a T-shirt. The wide open space of T-shirt fabric gives you lots of room to maneuver and isn’t too fiddly for your first time.

If you are using heat press vinyl on clothing, always remember to wash those clothes before you transfer the design onto them. If not, you may find that the fabric starts to contract around the transfer when you do wash it for the first time.

Remember that your vinyl cutter should only cut the heat transfer side of the vinyl and shouldn’t perforate the clear plastic backing. Don’t be tempted to increase the pressure so the machine cuts through the material as this will ruin the vinyl during the iron-on process.

So, now you know how to cut heat transfer vinyl — what will you be making first?

For more tutorials and guides aimed at helping you get the most out of your machine, be sure to visit our How To section.

Oh goodness. I’ve been trying to use my heat transfer vinyl with my Cameo for AGES and it keeps going wrong. I thought the clear backing had to be facing up!!!!! Doh!! Will try again this weekend.

Hi Mary,

Yes — clear backing should be facing DOWN. We’ve all been there! Good luck this weekend.

Hi y’all!

Thanks for this article. I’ve been trying to use the glittery heat transfer and am having real problems with the weeding process which I see you’ve had too. How did you get this to work in the end? Any good wedding knife recommendations? Don’t think mine is up to the job!

Thanks in advance.

Hi Lisa,

Agreed — weeding the glittery heat transfer vinyl is tough! All we can really recommend is plenty of practice and a good knife. We recommend the X-Acto X5262 knife set, which we use for absolutely everything to do with vinyl cutting. Definitely the best weeding knife on the market, IMHO!

Well done for these machine, but most of them are using for personal or for commercial? how to know the speed of it?

I gotta say I got a little intimidated at first when I found out I have to cut the vinyl in very specific ways and that it’s a science etc.. But after reading this I feel much lighter about doing this with my mom. Recently started working with htv so I’m pretty excited to be on the crafting end as well! Thanks!

It true.. weeding glitter transfer can be a real pain. For me it’s the toughest and most time consuming part. Will the X-Acto knife set make weeding easier? Maybe I should get one. Thanks for sharing!!

I usually use Siser Easy Weed but just purchased some Cricut Iron On Lite on sale. I have a heat press and I guess the word “lite” and the fact that Cricut only refers to using an iron has me a bit worried about using my heat press. Is the Cricut Iron On Lite HTV the same as Siser Easy Weed? Do you know if I would use the same settings on my heat press as I would with Siser Easy Weed? I have searched for this answer for hours and can’t find any reference to using a heat press with the Cricut brand HTV. Thanks!

I had serious issues with HTV Glitter and not cutting.. I think I found answers. To turn plastic side facing down. Will try this next time I have crafting time. I will also try changing needle.

Thank you for putting me back on my feet

What about cutting in a Brother Design N Cut machine? Any help would be great. I am using Siser HTV but it’s cutting the letter out and there is no way for me to place it on a Tshirt other than using transfer tape.