The world of crafting is a huge and exciting place. So huge and exciting, in fact, that it can sometimes be difficult to find your starting point.

We’re here to introduce you to our favorite crafting niche: vinyl cutting.

It’s one of the most interesting emerging craft markets that’s catching on with artsy people across the world. It’s catching on so well, in fact, that there are multiple vinyl cutting home businesses starting up every day as people follow their passion and decide to make some money out of it.

Vinyl cutting is great fun whether you are treating it as a business or a hobby. It’s a popular way to enjoy scrapbooking and making your own home decor, or to get started in sign-making or selling vinyl decals. Vinyl cutting machines come in a variety of sizes and shapes, but they all have one thing in common: they use a blade to cut the material into shapes or designs.

We’ve compiled this beginner’s guide to vinyl cutting to get you off the ground running with your new craft hobby or business.

Time to get crafty!

What is Vinyl Cutting?

Vinyl cutting is the act of creating a design (sometimes in a software program) then sending that design through to a vinyl cutter, which will cut out your design using a blade on sheets of vinyl.

Once the vinyl cutter has done its work, you then need to weed the cut vinyl sheets — removing all the waste vinyl from the paper backed sheet — and transfer the final design onto wherever you want it to go — on a car, for instance, your walls, cards, scrapbooks, you name it!

Don’t worry — weeding and transferring are actually pretty easy once you get the hang of it.

Vinyl Cutters

There are two types of vinyl cutters – those that are controlled by computers, and those that are operated manually.

The most sophisticated vinyl cutters are those that function as computer controlled machines.

They often look and behave a lot like printers, but instead of having a pen reproducing your work onto printer paper, vinyl cutters use a blade to cut your design into certain materials.

The software you use to design will export your creation from your computer to the vinyl cutter, controlling the movements of the blade like it would do with a printer.

Vinyl cutters are also known as craft cutters, die-cutters and plotters because the truth is, they can do far more than just cut your vinyl designs.

Important: While we use the term vinyl cutter, don’t be fooled in to thinking these machines can only cut vinyl! Modern draft cutters like the Cricut Maker are capable of working with over 300 different materials – meaning you can cut much more than sheets of vinyl.

As well as vinyl, high quality vinyl cutters are able to cut your designs into paper, cardstock, tissue paper, reflectives, thermal transfer material and much more. Some can even emboss your designs on wood and aluminium!

Manual Die Cutters

Here’s a look at how they work in action, using one of the most popular manual cutters — the Big Shot:

Examples of Popular Vinyl Cutting Machines

There are several companies that produce vinyl cutters, and you will undoubtedly be familiar with some of these names. They are major players in the craft space.

Let’s take a look at the top movers and shakers…

From Cricut

Cricut offers a wide variety of products for crafting, including machines, tools, materials, and accessories. We are in love with our Cricut Maker and it’s what we use for the many tutorials and projects on this site:

Cricut has three flagship craft cutters:

- Cricut Maker 3 — Billed as the most powerful desktop cutting machine Cricut has ever produced. This machine is capable of working with over 300 materials, using 13 custom tools (including engraving and debasing!). It cuts materials up to a width of 13 inches. [See Our Full Review]

- Cricut Explore 3 — Another popular desktop cutter. The Explore 3 works with 100+ materials, and 6 tools, but lacks the cutting force of the more expensive Maker. It shares the same cutting width of 13 inches. [See Our Full Review]

- Cricut Joy — A cheaper machine that is designed for smaller projects involving vinyl, yardstick and sticker paper. It cuts materials up to 5.5 inches wide. [See Our Full Review]

From Silhouette America

Silhouette America is the long-standing rival of Cricut, and an alternative producer of high quality vinyl cutters. They have two excellent machines that compete directly with the Cricut Maker and the Cricut Joy:

- Silhouette Cameo 4 — The Cameo 4 boasts comparable technology to the Cricut Maker and is known for its power, speed and cutting precision. Unlike the Maker, you can upsize to the Cameo PLUS for a 15 inch cutting width, or the Cameo 4 PRO for a mega 20 inch cutting width. If you need to cut large vinyl signage, this is the ‘dream machine’. [See Our Full Review]

- Silhouette Portrait 3 — A smaller and cheaper alternative to the Cameo 4, the Portrait 3 competes with the Cricut Joy as a portable cutter for small projects – but with a larger cutting width of 8 inches (vs the Joy’s 5.5″). [See Our Full Review]

From Other Companies

While Cricut and Silhouette are the biggest names in the craft cutting space, there are other companies selling vinyl cutters that will appeal to different needs.

- Sizzix sells one of the world’s most popular manual vinyl cutters — the Big Shot, which you can pick up in a cracking bundle deal over on Scrapbook.com. This is a lightweight die cutter that kids will absolutely adore – perfect for small craft projects with yardstick, vinyl or foam.

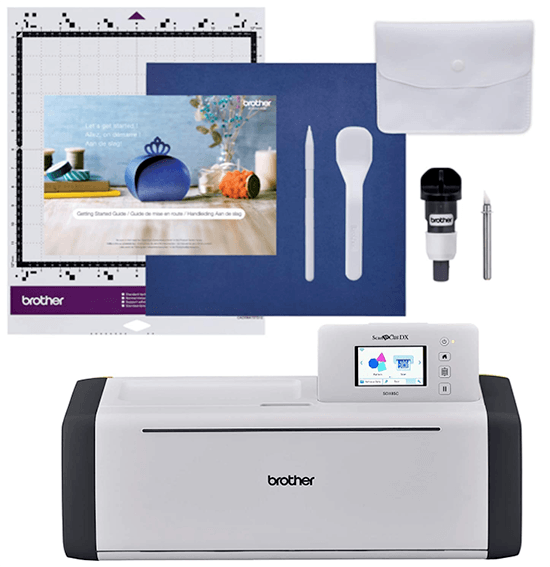

- Brother has had a cult following for its ScanNCut machine, which does… exactly what it says – letting you scan and cut projects to your heart’s content. More recently the company released the ScanNCut SDX series, which for our money is one of the most underrated machines in the vinyl cutting space. It’s the only option with a built-in scanner, which will appeal to anybody who wants to draw their own designs by hand before cutting.

- Finally, USCutter offers something different to the desktop cutters above. They have a variety of commercial cutters from best-in-class brands such as Roland and Graphtec. These machines cost thousands of dollars and are only really applicable to a full-scale signage business, but if that’s your jam? Worth checking out!

What Can I Make with a Vinyl Cutter?

You’re likely wondering, “that’s all very well, but what’s actually the point of craft cutting — what can I make with a vinyl cutter?”

The world is really your oyster in the vinyl cutting niche.

Here’s just a few things that crafters make with their vinyl cutters (like the popular Cricut Maker 3):

- Stickers and labels

- Home decor

- 3D objects

- Car wraps

- Electronic circuits

- Vinyl decals for laptops, smartphones and wallpaper

- T-shirt, cushion and mug transfers

- Cards and invitations

- Origami

- Paper crafts

- Signage

Put that imagination to work!

Vinyl Cutters for Hobbyists vs. Vinyl Cutters for Business

Many readers will be considering small business ideas where they can turn their passion in to a source of income.

There are those who enjoy the thrill of making crafts at home, the ‘hobbyists’ if you will. And there are those who need the machine for commercial purposes, and have to cater to the demands of clients and their whims.

The landscape is remarkably similar to the sewing crafts industry, where you have amateur enthusiasts buying the best DIY sewing machines for under $200, alongside power users who need something a little more ‘industrial’ for commercial sewing.

Anybody can get started on a budget.

But the exact needs will affect the type of machine required.

What types of businesses use a vinyl cutter?

Here’s some examples:

- Decal designers

- Signage businesses

- Home decor businesses

- Custom apparel brands

- Vehicle sticker brands and modders

- Small craft fans

Needless to say, many of the cheaper vinyl cutting machines are designed for light users and do not offer the precise cutting, or the larger printing surface, that is required by many businesses.

But these smaller, cheaper vinyl cutters are perfect for the hobbyists: they usually don’t take up too much space and are perfect for small designs. Some particularly high quality machines are able to deliver precision cuts for intricate designs.

Some of the recent flagship cutters released by companies like Cricut and Silhouette, however, are perfectly designed for both hobbyists and small businesses.

While they may not be quite as large as some of the commercial machines, they otherwise perfectly straddle the boundary between hobby and business, offering precision cutting, supreme versatility, and incredible efficiency.

Why Vinyl Cutting is Cheaper Than Ever Before

There was a time when the only people with access to commercial vinyl cutting machines were the large businesses that could afford to pay big upfront sums for the technology.

If you wanted to launch your own signage business, for instance you’d be dipping in to savings, talking to the bank — or seeking investment.

Thankfully, the advance of technology has seen huge cost savings in the production of personal vinyl cutters.

When you throw in the explosion of online craft businesses thanks to platforms like Etsy, there is huge growing demand for better machines from professionals and hobbyists alike.

Some of the companies that once specialised in commercial cutters have moved on to produce bestselling digital machines that can be purchased for under $199.

Likewise, an ‘economy’ market has emerged for professional-grade cutters — meaning we can now buy incredibly powerful equipment for less than $500, or industrial strength machines for less than $1000.

As the internet continues to throw up opportunities for craft fans to learn, share and sell their creations, we will see prices continue to fall and mainstream cutting technology continue to improve.

Good news, indeed!

How to Choose a Good Vinyl Cutting Machine

Electronic vs Manual Cutter

Do you want an electronic or a manual die cutter? They provide a completely different cutting experience so it’s worth thinking carefully about this before you buy.

Let’s have a look at how they compare:

– Can cut larger designs

– Can cut more intricate and challenging designs

– Can cut more materials

– More versatile with additional capabilities like drawing, embossing, stippling etc

– More powerful

– Quicker and more efficient to use

– Not limited to designs offered by die cuts and embossing folders

– Smaller footprint

– Quieter

– No need to use design software

– No need to connect to a computer

– Easy to use for beginners and kids

– Much cheaper

As you can see, there are a lot of fundamental differences between these two types of machines.

Generally speaking, we think manual cutters are best suited to occasional crafters and people unlikely to get too much mileage out of their craft cutter. Beginners and even children tend to prefer these machines as they’re simple, cheap and fun to use.

Electronic cutters on the other hand, are more suited to people who are looking for a little bit more from their cutter. They want versatility and a machine that will grow with them.

While they’re a little more expensive and slightly more complex to learn, electronic craft cutters really do allow you to make whatever your imagination so desires. They’re highly versatile, efficient and ideal for hobbyists and small businesses alike.

What Size Should My Machine Cut?

One of the first things you’ll notice shopping around is that vinyl cutters come in a wide range of cutting widths: from tiny 6-inch cutters like the Sizzix Big Shot, to GraphTec’s monstrous 64-inch FC8600 machine.

The bestselling cutters offer a maximum cutting width somewhere usually between 9-12 inches, which should be perfect for hobbyists and makers of small crafts — but may prove restrictive for other users.

Somebody selling t-shirts or crafts will have a pretty good idea of what size machine they require, but if you are launching a signage business, you will likely need greater flexibility and the ability to scale up.

The best way to think of this is simply: “How bothered would I be if I couldn’t cut a graphic slightly wider than a piece of A4?”

If the answer is “Very“, then go for a bigger machine.

If the answer is “Meh“, then the bestselling Silhouette or Cricut machines are probably your best option.

Don’t worry about specific models for now, we’ve reviewed them all for you in our vinyl cutter guide.

Two important issues to remember:

- Machines that offer larger cutting sizes are not necessarily better machines

- Maximum media size and maximum cutting size are two very different things!

For example, some manufacturers offer larger cutting capacity at lower quality (often using a stepper motor instead of digital servo). This is not the right option if you need precision.

Likewise, when a machine is advertised as Cutter XYZ 24 Inches, this is usually to indicate the maximum media size (i.e. the size of your vinyl sheet) that can be fed in to the machine — not the maximum cutting size, which is often buried further down in the product specifications.

What Machines Offer The Best Quality Cuts?

The expensive ones.

Sorry!

It’s true.

Let’s be realistic. You are not going to achieve the highest professional standards with a manual machine that costs you under $100. But don’t for one second simply write off this economy market — there are still good quality machines to be found.

Generally what we are looking for, quality-wise, is reliability, decent software, and a good motor.

Great cuts are also the result of great blades. So you’ll want a machine that supports the best of them — and you’ll need to be proactive at replacing them before they blunt!

Ideally, you’ll want one of the newest machines that are able to automatically adjust their pressure settings according to what material you feed it, like the Cameo 4 or the Cricut Maker 3. Older, less sophisticated machines made their users adjust the settings manually which resulted in a lot of errors, off cuts and ultimately waste — in both time and materials.

Regardless of what type of cutter you go for, your expectations play a big part. Don’t expect to find miracle products at bargain prices, but don’t neglect the cheaper models if you have less complex cutting needs either.

If you’re planning to run a craft business with your cutter, it’s worth considering whether you’ll have demanding clients who are likely to request intricate designs and very tight, precise maneuverings of your machine’s blades… that’s when you need to start paying up for more advanced technology.

What Software Will I Need?

Most vinyl cutters come with their own software that can be used to create basic designs, or to feed pre-existing templates and files that you’ve already created to the machine.

This is all you need to get started.

However, great cuts are born from great designs.

Many people assume that having access to the most expensive machine will dramatically improve their work, and in doing so they neglect the software where they actually create the work.

This is a big mistake.

Software is important.

The fastest way to improve your creations is to improve the design before it gets sent to the machine — i.e. in the software.

This involves practicing your design skills and making use of increasingly sophisticated software.

Three of the most popular design tools are:

Take a look at this video on how to use Adobe Illustrator to create vinyl decals, for example:

What about Photoshop?

Photoshop is great for most design work. The problem is that it relies on pixels and dots to create what is known as raster graphics. These can be of exceptionally high quality, which gives a hint as to why Photoshop is so damn popular.

It’s why, for example, we ‘Photoshop’ our holiday photos and selfies.

If you’re wondering why we don’t ‘Illustrate’ them instead, it’s because Adobe Illustrator deals with vectors instead of raster graphics.

That is, it uses lines instead of dots.

Lines speak the same language that your vinyl cutter speaks.

Our machines aren’t capable of translating dots from Photoshop in to movements of a blade. They rely on lines — vectors — to define a path.

There are methods of converting raster graphics (from Photoshop) in to vectors, but these can be pretty crude and we generally recommend you save yourself the bother.

Use vector-based software that can handle SVG (scalable vector graphics) files instead — i.e. one of the three options above.

What Support is Out There for Vinyl Cutters?

10 years ago, the hook that many manufacturers used of ‘Free Lifetime Phone Support‘ would have made a big difference to a considerable number of buyers.

Vinyl cutters take time to master.

Indeed, for those lacking DIY smarts, some of them take time just to assemble!

Phone support is a nice fallback and we understand why some users would value it over a manufacturer that ships the machine but does a poor job of providing support.

That said, times have changed and some of the best support you are likely to receive is not from the instruction manual or the technician on the phone — it’s from your fellow craft cutting enthusiasts.

Forums are bursting with discussion and tip trading on how to get the best results with Machines X, Y and Z.

YouTube is stacked to the rafters with outstanding videos that go above and beyond the basic requirements of showing you how to use each cutter.

If you feel like you’re going to need a lot of help getting to grips with your new machine, our advice is to stop before you purchase:

- Go to YouTube

- Search for your cutter of choice

- Ask yourself, “Are there plenty of useful looking tutorials?”

If the machine is well-supported by its community, this can be worth just as much as having a company technician on the end of a phone.

What Tools Do I Need To Start Vinyl Cutting?

Before you start vinyl cutting, you’ll need a few tools to set you on the road to success.

Aside from the vinyl cutting machine itself, most of these tools are reasonably priced and — if you’re responsible with them — should last a while from a small investment.

Here’s what you’ll need:

- Vinyl cutting machine and software (>>> Find the best prices for the top machines)

- Materials, like vinyl!

- Squeegee

- X-Acto Double Knife Set for weeding

- Transfer Tape

- Application Fluid, for transfer

Thankfully, some of the best craft cutter brands do some really generous bundle deals which throw in a load of materials and tools with their machines.

And that’s everything you need to know about vinyl cutting and vinyl cutting machines — any questions?